Iterations of hind leg printed with various size hinges and orientations on the print bed.

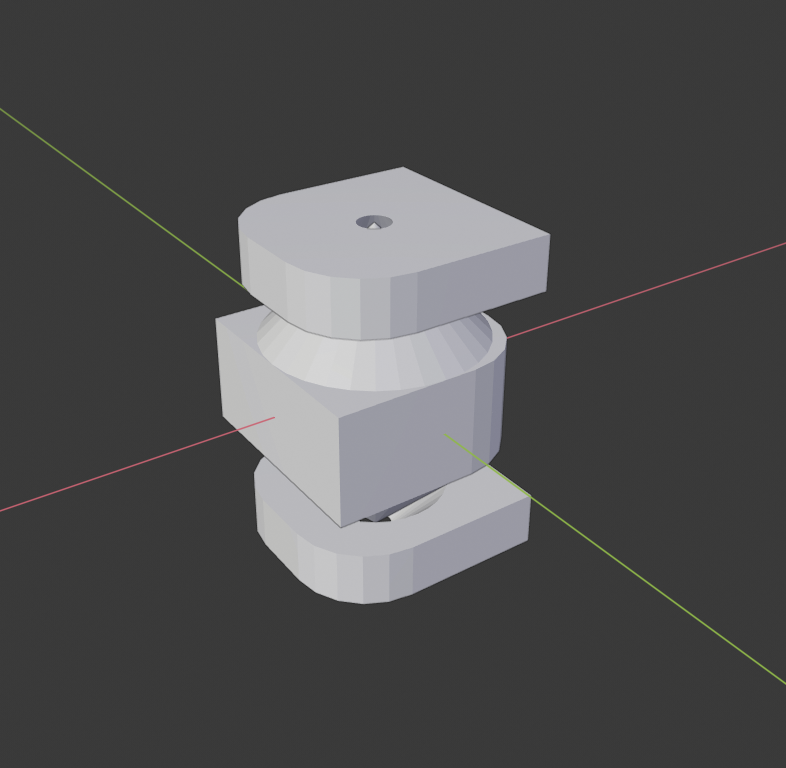

A cone in cone design hinge which I hope works well for 3D printing. The cone angle is 45º.

The exoskeletal bones of the honey bee have been replicated in a 3D model and I have started printing them to inspire methods of mechanical connection. Simple hinges and joints can be constructed with geometric shapes and then attached to the organic 3D model. Real honey bees have ball and socket style hinges in many of their leg components. This is a common method used by organisms with exoskeletons and is also found on crabs and lobsters. I added a hinge to the joints of the hind leg and started 3D printing and iterating with the model. They are quite small and the geometry becomes inaccurate at that size so I have been selectively scaling up the pieces and hinges when necessary. This process is not unlike natural selection and indeed my parts are evolving to function properly. However, I am deliberately guiding the part to be like a honey bee, so the comparison is casual. I hope that this process will move more quickly with the other legs, and body parts. I will likely borrow findings from my monarch butterfly when constructing the thorax. I believe the real smallest parts like antenna and feet will not be 3D printed.

This project is not currently being funded or have a client, however I do have a potential market in mind. I would like to create a kit and through its construction, the viewer learns the anatomy of arthropods, mechatronics, and then owns a starting point for creativity. Essentially, you can build your own bee.